Qingchen Shen

Summer is almost here, bringing higher temperatures and prompting many of us to crank up the air conditioning on particularly hot days. The downside to A/C is that the units gobble up energy and can emit greenhouse gases, contributing further to global warming. Hence, there is strong interest in coming up with eco-friendly alternatives. Scientists from the University of Cambridge have developed an innovative new plant-based film that gets cooler when exposed to sunlight, making it ideal for cooling buildings or cars in the future without needing any external power source. They described their work at a recent meeting of the American Chemical Society.

The technical term for this approach is passive daytime radiative cooling (PDRC), so named because it doesn’t require an injection of energy into the system to disperse heat. The surface emits its own heat into space without being absorbed by the air or atmosphere, thereby becoming several degrees cooler than the surrounding air without needing electrical energy.

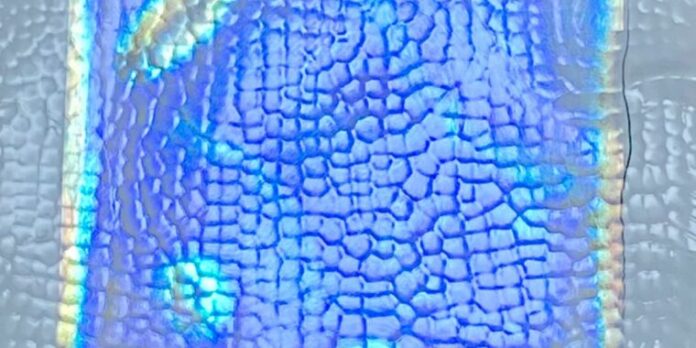

“We know there is spontaneous thermal transfer between objects with different temperatures,” Qingchen Shen said at a press conference during the meeting. Their cooling technology exploits that thermal transfer, with a twist. Most PDRC materials (paints, films, and so forth) are white, or have a mirrored finish, to achieve a broadband reflection of sunlight. Pigments or dyes interfere with that since they absorb specific wavelengths of light and only reflect certain colors, thereby transforming energy from the light into heat. The films created by Shen et al. are colored, but it is structural color in the form of nanocrystals, not due to adding pigments or dyes. So color can be added without sacrificing the passive cooling efficiency.

As previously reported, the bright iridescent colors in butterfly wings, soap bubbles, or beetle shells, for example, don’t come from any pigment molecules but from how the wings are structured—a naturally occurring example of what physicists call photonic crystals. In nature, scales of chitin (a polysaccharide common to insects) are arranged like roof tiles. Essentially, they form a diffraction grating, except photonic crystals only produce specific colors, or wavelengths, of light, while a diffraction grating will produce the entire spectrum, much like a prism. Also known as photonic band gap materials, photonic crystals are “tunable,” which means they are precisely ordered to block certain wavelengths of light while letting others through. Alter the structure by changing the size of the tiles, and the crystals become sensitive to a different wavelength.

Scientists can make their own structural colored materials in the lab, but it can be challenging to scale up the process for commercial applications without sacrificing optical precision. So creating structural colors like those found in nature is an active area of materials research.

For example, last year, Massachusetts Institute of Technology scientists adapted a 19th century holographic photography technique invented by physicist Gabriel Lippmann to develop chameleon-like films that change color when stretched. The films would be ideal for making bandages that change color in response to pressure, letting medical professionals know if they are wrapping a wound too tightly—an important factor when treating conditions like venous ulcers, pressure ulcers, lymphoedema, and scarring. Children would love wearing bandages that change color, providing a boon for pediatricians. And being able to make large sheets of the material opens up applications in apparel and sportswear.

A good PDRC material must stay cooler than the air around it during the day, which means it has to reflect a lot of sunlight without absorbing it. Shen and his cohorts decided to work with plant-based materials for their passive-cooling iridescent films, specifically cellulose. “Cellulose is the most abundant polymer in nature,” Shen said about their choice of material. “You can easily find the cellulose in wood or cotton. As a natural material, cellulose is sustainable and biocompatible. And it almost doesn’t absorb solar energy and has a very high thermal emissivity in the infrared band. These properties are critical for achieving radiative cooling.”

The trick is to use two distinct layers with different functions. One layer is comprised of cellulose nanocrystals, which can be extracted from renewable sources like wood, per Shen. Once extracted, the nanocrystals are dispersed in water, and as the water evaporates, the nanocrystals self-assemble into a photonic crystal structure. So the resulting film will reflect visible light at specific wavelengths to get those aesthetically pleasing colors—in this case, light green and blue, although Shen said that one could adjust the cellulose nanocrystal suspension to get other colors like red.

The second layer is made of porous ethylcellulose, which serves to scatter any light that manages to penetrate the cellulose nanocrystal layer. Between the two layers, one gets both the color and the broadband solar reflection properties required for PDRC. When Shen et al. measured the performance of their colored films under sunlight, they found that the films were nearly 40° F cooler than the surrounding air and that a square meter of film generated some 120 watts of cooling power—comparable to an average home A/C unit.

The researchers are confident their manufacturing process can be sufficiently scaled up for commercial applications; they can already make them several meters at a time using a standard manufacturing line. In addition to being used to passively cool buildings and cars—the availability of colors would make the films especially attractive to the automotive industry, per Shen—the films could be adapted as sensors to detect shifts in the weather or pollution levels. The team is also experimenting with adding texture to the ethylcellulose layer of their films, like that found in different kinds of wood finishes, which could make them more attractive for use in homes or other buildings.